BONDING WIRE

Mpempe akwụkwọ EZIOKWU OKWU ỌMA

Gịnị bụ Wire Bonding?

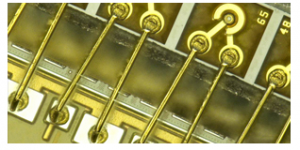

Njikọta waya bụ usoro eji ejikọta ogologo obere dayameta eriri igwe dị nro na elu igwe dakọtara na-enweghị iji solder, flux, na n'ọnọdụ ụfọdụ na-eji okpomọkụ karịa 150 degrees Celsius. Ọla dị nro gụnyere ọla edo (Au), ọla kọpa (Cu), Silver (Ag), Aluminium (Al) na alloys dị ka Palladium-Silver (PdAg) na ndị ọzọ.

Ịghọta usoro na usoro ijikọ waya maka ngwa Mgbakọ Micro Electronics.

Usoro / Usoro ijikọ wedge: Ribbon, Thermosonic Ball & Ultrasonic Wedge Bond

Njikọta waya bụ usoro nke ime njikọ n'etiti sekit agbakwunyere (IC) ma ọ bụ ngwaọrụ semiconductor yiri ya na ngwugwu ya ma ọ bụ freframe ya n'oge nrụpụta. A na-ejikarị ya eme ihe ugbu a iji nye njikọ eletriki na ngwugwu batrị lithium-ion. A na-ewere njikọ waya dị ka ihe kachasị ọnụ ahịa na mgbanwe nke teknụzụ njikọ njikọ microelectronic dị, ma jiri ya mee ihe n'ọtụtụ nchịkọta semiconductor emepụtara today. bụ ọtụtụ usoro ijikọ waya, nke gụnyere: Thermo-Compression Wire Bonding:

Thermo-mkpakọ waya bonding (ijikọta na eleghi anya na elu (na-emekarị Au) ọnụ n'okpuru a clamping ike na elu interface okpomọkụ, ọ na-adịkarị karịa 300°C, na-emepụta weld), e mepụtara na mbụ na 1950's maka microelectronics interconnects, Otú ọ dị nke a bụ. Ngwa ngwa dochie anya Ultrasonic & Thermosonic bonding na 60 si dị ka isi interconnect technology. Thermo-mkpakọ bonding ka na-eji maka niche ngwa taa, ma n'ozuzu ezere site na-emepụta n'ihi na elu (na-emebikarị) interface okpomọkụ dị mkpa iji mee ka a ọma bond.Ultrasonic Wedge Waya Bonding:

N'afọ ndị 1960 Ultrasonic wedge wire bonding ghọrọ usoro njikọ njikọ kachasị. Ngwa nke ịma jijiji ugboro ugboro (site na transducer resonating) na ngwaọrụ njikọ na ike njigide n'otu oge, kwere ka eriri Aluminom na ọla edo gbado n'ime ụlọ okpomọkụ. Nke a Ultrasonic vibration na-enyere aka n'iwepụ ihe ndị na-emerụ emerụ (oxides, adịghị ọcha, wdg) site na njikọ njikọ na mmalite nke usoro njikọ, na ịkwalite uto intermetallic na-emepewanye ma wusie njikọ ahụ ike. Ahụkarị frequencies maka bonding bụ 60 – 120 KHz. The ultrasonic wedge Usoro nwere abụọ isi usoro teknụzụ: Nnukwu (arọ) waya bonding maka>100µm dayameta wiresFine (obere) waya bonding maka <75µm dayameta wires Ihe atụ nke ahụkarị Ultrasonic bonding cycles nwere ike ịhụ ebe a. maka ezi waya na ebe a maka nnukwu wire.Ultrasonic wedge waya bonding eji a kpọmkwem bonding ngwá ọrụ ma ọ bụ "wedge," nke a na-arụkarị site na Tungsten Carbide (maka waya Aluminom) ma ọ bụ Titanium Carbide (maka waya ọla edo) dabere na usoro chọrọ na dayameta waya; seramiiki tipped wedges maka ngwa dị iche iche dịkwa. Thermosonic Wire Bonding:

Ebe a na-achọrọ mgbakwụnye mgbakwunye (ọkachasị maka waya ọla edo, yana njikọ njikọta na nso 100 – 250°C), a na-akpọ usoro a njikọ waya Thermosonic. Nke a nwere nnukwu uru n'elu omenala thermo-mkpakọ usoro, dị ka ukwuu ala interface okpomọkụ a chọrọ (Au bonding na ụlọ okpomọkụ e kwuru ma na omume ọ bụ unreliable enweghị ọzọ okpomọkụ) .Thermosonic Ball Bonding:

Ụdị ọzọ nke Thermosonic waya bonding bụ Ball Bonding (lee bọọlụ njikọ okirikiri ebe a). Usoro a na-eji seramiiki capillary bonding ngwá ọrụ n'elu omenala wedge aghụghọ iji jikọta àgwà kacha mma na ma thermo-mkpakọ na ultrasonic bonding na-enweghị ihe ndọghachi azụ. Thermosonic vibration ana achi achi na interface okpomọkụ na-anọgide na ala, mgbe mbụ interconnect, thermally-compressed ball bond na-enye ohere ka a na-etinye waya na njikọ nke abụọ n'akụkụ ọ bụla, ọ bụghị n'ahịrị na nkekọ mbụ, nke bụ ihe mgbochi na njikọta waya Ultrasonic. . N'ihi na akpaka, elu olu rụpụta, bọọlụ bonders bụ nke ukwuu ngwa ngwa karịa Ultrasonic / Thermosonic (wedge) bonders, na-eme Thermosonic bọl bonding na-achị interconnect technology na microelectronics ikpeazụ 50+ afọ. Ribbon bonding:

Ribbon bonding, tinye n'ọrụ dị larịị ọla teepu, na-achị na RF na Microwave electronics ruo ọtụtụ iri afọ (rịbọn na-enye ọganihu dị ịrịba ama na mgbaama ọnwụ [akpụkpọ ahụ mmetụta] megide omenala gburugburu waya). A na-ejikọta obere rịbọn ọla edo, nke na-adịkarị ruo 75µm n'obosara na 25µm, site na usoro Thermosonic na nnukwu ihe mkpuchi wedge nwere ihu dị larịị. ihe achọrọ maka loop ala, njikọ njikọ njupụta dị elu abawanyela.

Gịnị bụ gold bonding waya?

Njikọ waya ọla edo bụ usoro eji ejikọta waya ọla edo na isi abụọ na mgbakọ iji mepụta njikọ ma ọ bụ ụzọ na-eduzi ọkụ eletrik. A na-eji ọkụ, ultrasonics, na ike rụọ ọrụ iji mepụta ihe mgbakwunye maka waya ọla edo. Usoro nke ịmepụta ihe mgbakwunye na-amalite site na ịmepụta bọọlụ ọla edo n'ọnụ ọnụ nke eriri eriri waya, capillary. A na-agbanye bọọlụ a n'elu ebe mgbakọ na-ekpo ọkụ mgbe ị na-etinye ma ngwa-ngwa kpọmkwem nke ike na ugboro 60kHz - 152kHz nke ultrasonic ngagharị na ngwá ọrụ. otu esi etolite ụdị loop kwesịrị ekwesị maka geometry ọgbakọ. A na-etolite njikọ nke abụọ, nke a na-akpọkarị stitch, n'elu nke ọzọ site na ịpịnye waya na iji mgbachi na-adọwa waya na njikọ ahụ.

Njikọ waya ọla edo na-enye usoro njikọ n'ime ngwugwu nke na-eduzi ọkụ eletrik, ọ fọrọ nke nta ka ọ bụrụ usoro ịdị ukwuu karịa ụfọdụ ndị na-ere ahịa. Na mgbakwunye, wires ọla edo nwere oke oxidation dị elu ma e jiri ya tụnyere ihe waya ndị ọzọ ma dị nro karịa ọtụtụ, nke dị mkpa maka ebe dị nro.

Usoro ahụ nwekwara ike ịdịgasị iche dabere na mkpa nke mgbakọ ahụ. Site na ihe ndị na-emetụ n'ahụ, enwere ike itinye bọọlụ ọla edo na mpaghara njikọ nke abụọ iji mepụta ma njikọ siri ike na njikọ "dị nro" iji gbochie mmebi n'elu akụkụ ahụ. Site na oghere siri ike, enwere ike iji otu bọọlụ dị ka mmalite maka nkekọ abụọ, na-akpụ njikọ “V”. Mgbe njikọ waya chọrọ ka ọ sie ike karị, enwere ike itinye bọọlụ n'elu stitch iji mepụta njikọ nchekwa, na-abawanye nkwụsi ike na ike nke waya. Ọtụtụ ngwa dị iche iche na ọdịiche dị na njikọ waya bụ ihe na-akparaghị ókè yana enwere ike nweta ya site na iji ngwanrọ akpaaka na sistemụ njikọ waya nke Palomar.

Mmepe njikọ waya:

Achọpụtara njikọ waya na Germany n'afọ ndị 1950 site na nleba anya nnwale ma emesịa mepụta ya ka ọ bụrụ usoro a na-achịkwa nke ukwuu. Taa, a na-eji ya nke ukwuu maka njikọ eletriki semiconductor chips na ngwugwu ngwugwu, isi diski diski na ngwa amplifiers, yana ọtụtụ ngwa ndị ọzọ na-enye ohere ka ihe ndị a na-eme kwa ụbọchị na-adị ntakịrị, “mara mma” na nke ọma.

Ngwa njikọ waya

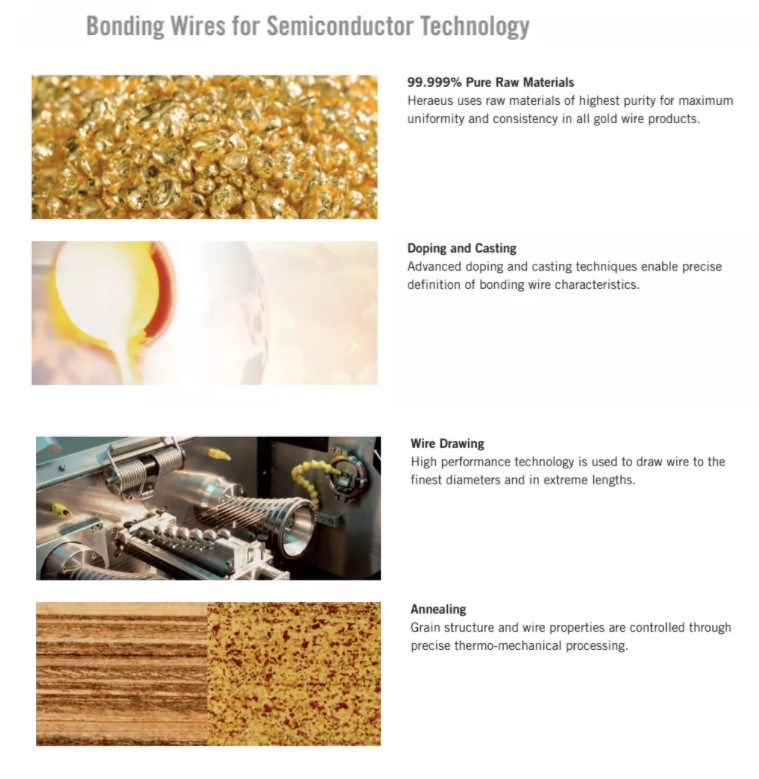

Mmụba miniaturization na ngwá electronic arụpụtala

na bonding wires na-aghọ ihe dị mkpa mejupụtara nke

eletrọnịkị mgbakọ.

N'ihi nke a ezi na ultrafine bonding wires nke

ọla edo, aluminum, ọla kọpa na palladium na-eji. Kachasị elu

A na-achọrọ maka ịdịmma ha, ọkachasị n'ihe gbasara

ka uniformity nke waya Njirimara.

Dabere na ha chemical mejupụtara na kpọmkwem

Njirimara, a na-eme ka eriri ndị na-ejikọta ya na njikọ

usoro họrọ na ka akpaka bonding igwe dị ka

nakwa maka ihe ịma aka dị iche iche na teknụzụ mgbakọ.

Heraeus Electronics na-enye ngwaahịa dị iche iche

maka ngwa dị iche iche nke

Ụlọ ọrụ ụgbọ ala

Nzikọrịta ozi

Ndị na-emepụta semiconductor

Ụlọ ọrụ ngwaahịa ndị ahịa

Otu ngwaahịa ngwaahịa Heraeus Bonding Wire bụ:

Njide wires maka ngwa na rọba jupụtara

akụrụngwa eletrọnịkị

Aluminom na aluminom alloy bonding wires maka

ngwa nke chọrọ obere nhazi okpomọkụ

Ọla kọpa bonding wires dị ka teknụzụ na

echekwa ọzọ ka gold wires

Mpịakọta njikọ nke ọla dị oké ọnụ ahịa na nke na-adịghị ọnụ ahịa maka

njikọ eletrik na mpaghara kọntaktị buru ibu.

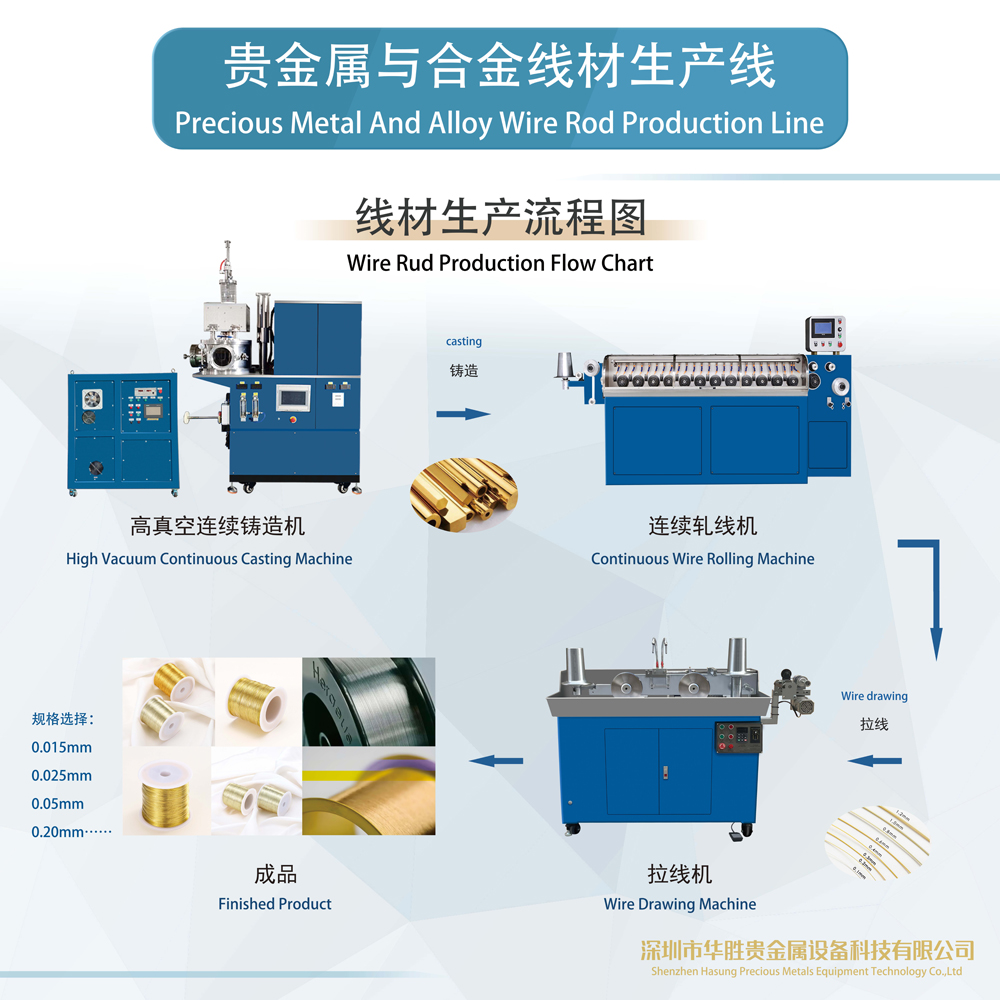

Ngwakọta Wires Production Line

Oge nzipu: Jul-22-2022