Osisi Atomization ntụ ntụ

Ime metal ntụ ntụ

NkePokwaMEtallurgy (PM) usoro na-eme ka ígwè powders.

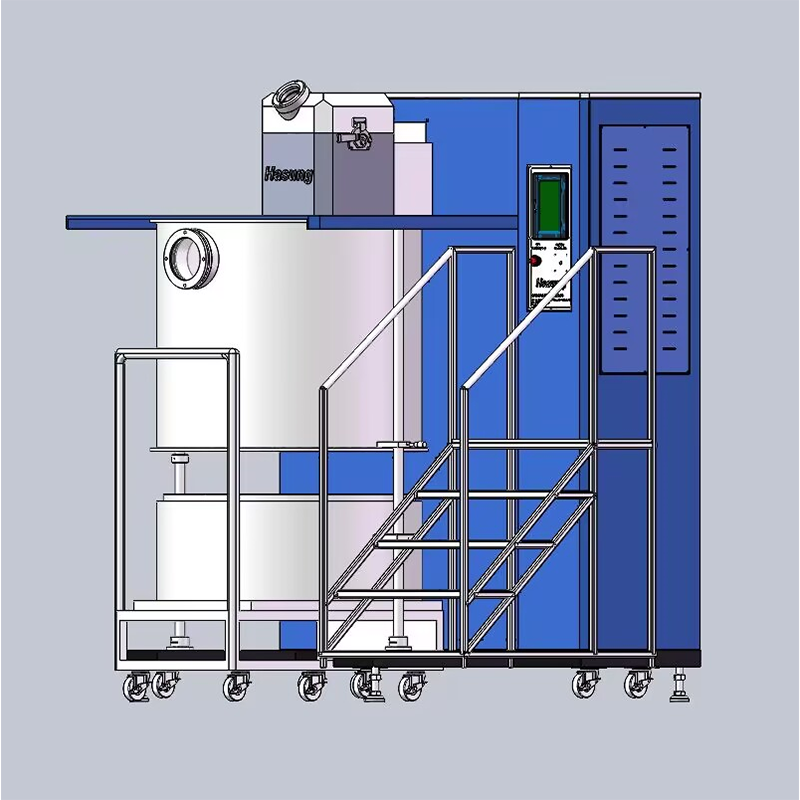

Igwe ahụntụ ntụ mmiri atomizera na-eji emepụta nnukwu mma na homogenous nna ukwu grains na alloy grains, nakwa ntụ ntụ, na-amalite site na akụrụngwa gbazere site induction kpo oku na ikuku na-echebe, na mgbe ahụ, mgbe nkedo na ntụ ntụ, ga-anakwere elu nrụgide egbe mmiri agbaze gbazee. metal n'ime ezi urughurus. A na-ejikarị ya eme ihe na ụlọ ọrụ nchacha igwe.

The Gas Atomizer bụmara site na obere mmetọ gburugburu ebe obibi, ọkwa dị elu nke uzuzu uzuzu, obere ikuku oxygen na ngwa ngwa jụrụ oyi na ihe ndị ọzọ. Site na ọtụtụ afọ 'mgbe ọhụrụ ọhụrụ na mma, anyị ụlọ ọrụ emelitere anyị gas atomization ntụ ntụ-emepụta Usoro na nkà na ụzụ ọtụtụ ugboro iji na-emepụta metal na alloy powders nke elu arụmọrụ. Ka ọ dị ugbu a, nkà na ụzụ aghọwo ihe na-eduga n'ịkwado na ịkwalite atomization ntụ ntụ na-emepụta ihe, nchọpụta ihe ọhụrụ na mmepe nkà na ụzụ ọhụrụ.

Usoro ọrụ nke atomizing akụrụngwa na-ezo aka na ntụ ntụ-emepụta usoro nke na-agbaze metal ma ọ bụ alloy n'okpuru ụfọdụ ọnọdụ na metal mmiri mmiri wụsara obliquely ka okpomọkụ ichebe crucible na-asọpụta site na mmiri mmiri ntughari ọnụ (ala), na-ewere ohere nke elu nrụgide gas nke nozzle. iji gwepịa mmiri mmiri igwe n'ime nnukwu mmiri dị mma na obere mmiri mmiri; Mmiri mmiri na-efe efe na-adaba n'ime ọdịdị bọlbụ ma ọ bụ ihe dị n'ụdị bọọlụ ma si otú ahụ mezue usoro mmepụta ntụ ntụ.Ọtụtụ n'ime, eji na metal 3D obibi ụlọ ọrụ.

-

Igwe Ọdụdọ Ọlaedo Na-eme Ngwa Maka Nnụcha ọla edo

Okwu mmalite:

1. Nabata ntinye ugboro ugboro nke ọkara, oge ịgbaze obere oge na ịrụ ọrụ dị elu.

2. Ụlọ na-agbaze na-etinye gas inert nke a na-eji egbochi oxidation nke ihe ígwè na ntinye nke adịghị ọcha. Maka nzube a, ọ dị mma maka ihe ndị dị elu na-adị ọcha ma ọ bụ ihe na-agbaze nke nwere ihe ndị dị mfe oxidized.

3. The n'ibu ịkpali ọrụ n'okpuru agụụ steeti na-nakweere, na agba e guzobere na-adịghị segregated.

4. The smelting na-echebe site elu-ọcha inert gas, otú graphite ruthenium nwere nnọọ nta oxidation ọnwụ.

5. Iji Taiwan Weinview / Siemens PLC njikwa, ọrụ dị mfe.

6. A na-ekpo ọkụ na-akpaghị aka n'oge a na-agbanye mmiri iji hụ na nkedo dị mma.

7. Na ọtụtụ ụwa ama ụdị components iji hụ na adịchaghị mma.8. A na-ejikarị eme ihe maka nnụcha ọla edo.

-

Metal Powder Water Atomizer Maka Metal Platinum Palladium Steel dị oke ọnụ ahịa

Nkọwapụta ngwaahịa

Induction kpo oku n'okpuru nchebe nke inert gas, na-eji graphite crucible, na-agbaze okpomọkụ ruo 1600 degrees. Enwere ike iji ụdị okpomọkụ dị elu HT, na-eji seramiiki crucible (graphite susceptor), okpomọkụ na-agbaze nwere ike iru ogo 2000. Enwere ike ịgbakwunye usoro ọkụ ọkụ na-ekpo ọkụ, ebe gas na-ekpo ọkụ na ogo 500 maka ịmepụta ntụ ntụ dị mma. Akụrụngwa ahụ na-emepụta powders metal sppherical na ezigbo mmiri na nha nha n'etiti 10 na 200 microns, ọbụna karịa # 400, 500 #. Enwere ike iji ya n'ichepụta usoro dịka laser selective sintering na uzuzu metallurgy.Uru nke akụrụngwa usoro Hasung AU:

- Kọmpat Ọdịdị na mfe ọrụ

- Mgbanwe na arụ ọrụ nke ọma nke obere batches nke ntụ ntụ ígwè

- Mfe na ngwa ngwa alloy mgbanwe na nozzle nnọchi

- Ọnụego mmịpụta ntụ ọka dị elu yana ọnụ ahịa mbelata dị ka 1/1000

– Stable mmepụta usoroAkụkụ dị mkpa nke ngwaọrụ Hasung AU Series:

- Enwere ike ikpo ọkụ graphite crucible ruo ogo 2000 na gburugburu gas na-echebe

- moto induction na-achịkwa Microprocessor (400 volts, ike nke 3)

- Ọmarịcha ọrụ ngwakọta igwe mmiri mmiri, nke nwere ike ịgbaze ma gbazee ọla dị iche iche tupu atomization gas

- Na gburugburu ebe nchekwa gas, enwere ike ịgbakwunye usoro nri iji gbanwee ihe mejupụtara alloy

- Njikwa okpomọkụ ziri ezi site na iji ụdị N-ụdị thermocouples

- ike crucible 1500cm3, 3000cm3 na 12000cm3 nhọrọ

- Jiri argon ma ọ bụ nitrogen ruo ikuku 30

- Enwere ike ịgbakwunye usoro kpo oku gas iji kpoo gas na ogo 500 maka mmepụta nke powders na obere ihe.

- Ngwa ngwa na mfe ịmafe n'etiti abụọ-egwe ọka ụdịdị maka ịrụ ọrụ nke ọma mmepụta nke powders nke dị iche iche urughuru nha

- Kachasị ụkpụrụ ikuku ikuku iji zere irighiri satịlaịtị maka ezigbo ntụ ntụ

- Mkpokọta ntụ ntụ ígwè akọrọ na ụlọ elu na-ekpofu uzuzu n'okpuru gas nchebe

- Nchịkọta nke nra site na nzacha pneumatic

- Nwere ike ịchekwa ihe karịrị ntọala paramita 100

- Enwere ike iji ngwaọrụ GSM rụọ ọrụ nke ọma -

100 ntupu – 400 ntupu Metal ntụ ntụ Water Atomizer Machine

Ọ na-adabara maka ịme ntụ ntụ (ma ọ bụ granular) ihe na tankị atomizing mgbe agbaze ọla ma ọ bụ alloys metal (enwere ike iji agbaze nkịtị ma ọ bụ oghere oghere). A na-ejikarị eme ihe na mahadum, ụlọ ọrụ nyocha sayensị, wdg. Metal atomization powder nwere ike ịmepụta site na nnukwu nsogbu mmiri atomization dị ka ngwa ntụ ntụ.

Ngwa a dịkwa mma maka mmepụta na nyocha nke mmepụta ihe mgbakwunye ọla edo (nchacha ọla edo) nkwadebe ntụ ntụ na mahadum na ụlọ ọrụ nyocha sayensị.

Ngwa ahụ dịkwa mma maka nyocha na mmepụta nke ụdị igwe anaghị agba nchara, alloy steel, ntụ ntụ ọla kọpa, ntụ ntụ aluminum, ntụ ntụ ọlaọcha, seramiiki ntụ ntụ na ntụ ntụ brazing.