Ngwaahịa

-

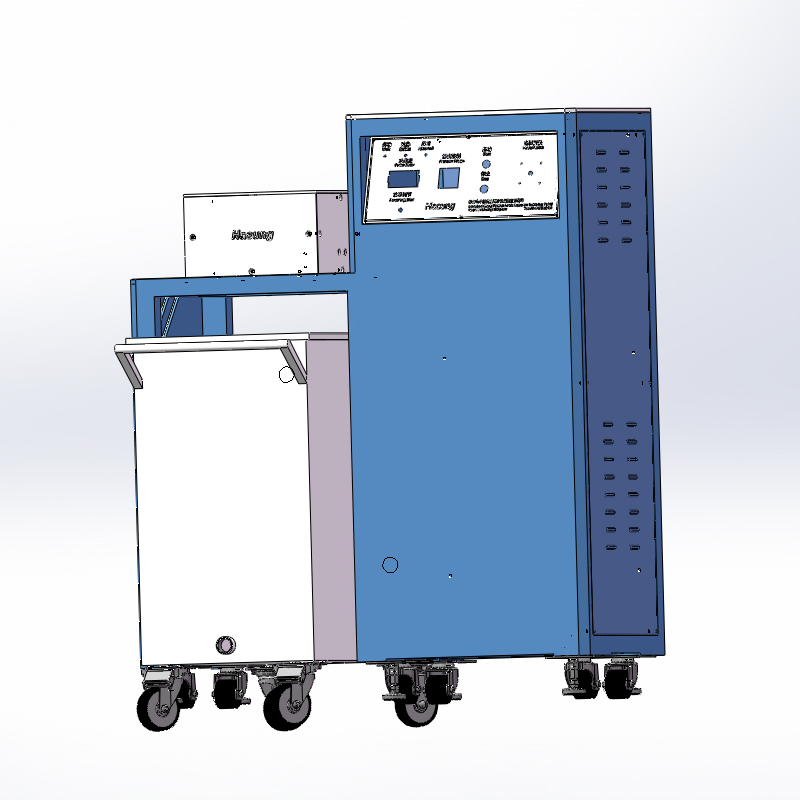

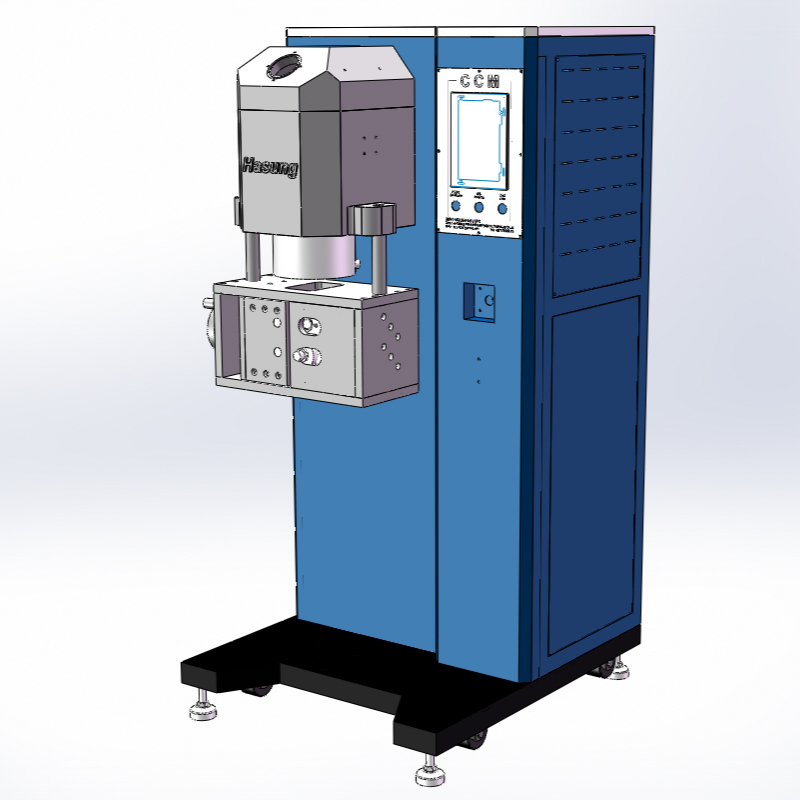

Metal Granulating Machine maka ọla edo ọla kọpa Alloy 20kg 30kg 50kg 100kg 150kg

1. Na njikwa okpomọkụ, izi ezi ruo ± 1 ° C.

2. Ultra-mmadụ imewe, ọrụ dị mfe karịa ndị ọzọ.

3. Jiri njikwa Mitsubishi ebubata.

4. Silver Granulator na njikwa tempterature (Gold Silver Grains Casting Machine, Silver Granulating Machine).

5. Igwe a na-eji teknụzụ kpo oku IGBT dị elu, mmetụta nkedo dị mma nke ukwuu, usoro ahụ kwụsiri ike ma dị mma, ikike ọla edo gbazere bụ nhọrọ, na nkọwapụta igwe granulated bụ nhọrọ.

6. The granulation ọsọ bụ ngwa ngwa na ọ dịghị mkpọtụ.Nnwale dị elu na ọrụ nchebe zuru oke na-eme ka igwe dum dị mma ma dịgidere.

7. Igwe ahụ nwere nhazi nkewa na ahụ nwere ohere n'efu.

-

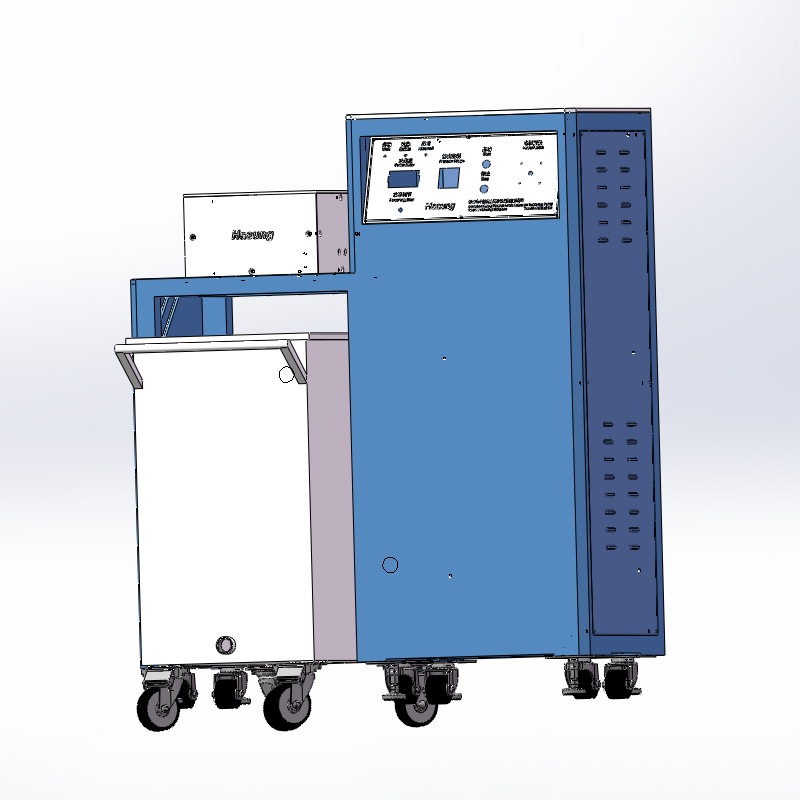

Ngwa kọmpat nha igwe granulator granulating maka ọla edo ọla edo

Ndị na-agba agba ígwè dị obere.Site na njikwa okpomọkụ, izi ezi ruru ±1°C.

Ultra-mmadụ imewe, ọrụ dị mfe karịa ndị ọzọ.

Jiri njikwa Mitsubishi ebubata.

Tinye maka igwe ihe nkedo vacuum pressure, nke nwere tank mmiri 304 SS.Granulator nwere njikwa okpomọkụ (igwe nkedo ọla edo ọla edo, igwe granulating ọla ọcha).

Igwe a na-anabata teknụzụ kpo oku IGBT dị elu nke Germany, mmetụta nkedo dị mma nke ukwuu, sistemu ahụ kwụsiri ike ma dịkwa mma, ikike ọla edo gbazere bụ nhọrọ, yana nkọwapụta igwe granulated bụ nhọrọ.The granulation ọsọ bụ ngwa ngwa na ọ dịghị mkpọtụ.Nnwale dị elu na ọrụ nchebe zuru oke na-eme ka igwe dum dị mma ma dịgidere.Igwe ahụ nwere nhazi nkewa na ahụ nwere ohere n'efu.Iji na-enweghị ikuku compressor, nkedo site na aka igwe oghere nkwụsị.

Nke a AG Series granulating usoro dabara maka obere ikike site na 1kg ruo 6kg ikike (ọlaedo), ọ dị mma maka ndị ahịa nwere obere ohere.

-

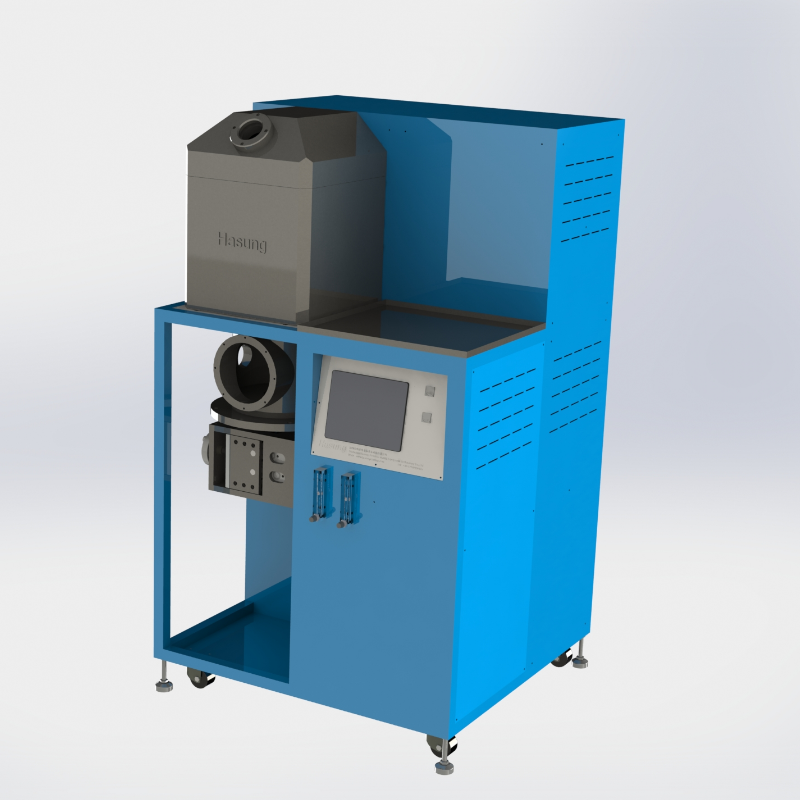

Metal Powder Water Atomizer Maka Metal Powder ọla edo ọla kọpa

Nkọwapụta ngwaahịa

Induction kpo oku n'okpuru nchebe nke inert gas, na-eji graphite crucible, na-agbaze okpomọkụ ruo 1600 degrees.Enwere ike iji ụdị okpomọkụ dị elu HT, na-eji seramiiki crucible (graphite susceptor), okpomọkụ na-agbaze nwere ike iru ogo 2000.Enwere ike ịgbakwunye usoro ọkụ ọkụ na-ekpo ọkụ, ebe gas na-ekpo ọkụ na ogo 500 maka ịmepụta ntụ ntụ dị mma.Akụrụngwa ahụ na-emepụta powders metal sppherical na ezigbo mmiri na nha nha n'etiti 10 na 200 microns, ọbụna karịa # 400, 500 #.Enwere ike iji ya n'ichepụta usoro dịka laser selective sintering na uzuzu metallurgy.Uru nke akụrụngwa usoro Hasung AU:

- Kọmpat Ọdịdị na mfe ọrụ

- Mgbanwe na arụ ọrụ nke ọma nke obere batches nke ntụ ntụ ígwè

- Mfe na ngwa ngwa alloy mgbanwe na nozzle nnọchi

- Ọnụego mmịpụta ntụ ọka dị elu yana ọnụ ahịa mbelata dị ka 1/1000

– Stable mmepụta usoroAkụkụ dị mkpa nke ngwaọrụ Hasung AU Series:

- Enwere ike ikpo ọkụ graphite crucible ruo ogo 2000 na gburugburu gas na-echebe

- moto induction na-achịkwa Microprocessor (400 volts, ike nke 3)

- Ọmarịcha ọrụ ngwakọta igwe mmiri mmiri, nke nwere ike ịgbaze ma gbazee ọla dị iche iche tupu atomization gas

- Na gburugburu ebe nchekwa gas, enwere ike ịgbakwunye usoro nri iji gbanwee ihe mejupụtara alloy

- Njikwa okpomọkụ ziri ezi site na iji ụdị N-ụdị thermocouples

- ike crucible 1500cm3, 3000cm3 na 12000cm3 nhọrọ

- Jiri argon ma ọ bụ nitrogen ruo ikuku 30

- Enwere ike ịgbakwunye usoro kpo oku gas iji kpoo gas na ogo 500 maka mmepụta nke powders na obere ihe.

- Ngwa ngwa na mfe ịmafe n'etiti abụọ-egwe ọka ụdịdị maka ịrụ ọrụ nke ọma mmepụta nke powders nke dị iche iche urughuru nha

- Kachasị ụkpụrụ ikuku ikuku iji zere irighiri satịlaịtị maka ezigbo ntụ ntụ

- Mkpokọta ntụ ntụ ígwè akọrọ na ụlọ elu na-ekpofu uzuzu n'okpuru gas nchebe

- Nchịkọta nke nra site na nzacha pneumatic

- Nwere ike ịchekwa ihe karịrị ntọala paramita 100

- Enwere ike iji ngwaọrụ GSM rụọ ọrụ nke ọma -

-11.jpg)

100 ntupu – 400 ntupu Metal ntụ ntụ Water Atomizer Machine

Ọ na-adabara maka ịme ntụ ntụ (ma ọ bụ granular) ihe na tankị atomizing mgbe agbaze ọla ma ọ bụ alloys metal (enwere ike iji agbaze nkịtị ma ọ bụ oghere oghere).A na-ejikarị eme ihe na mahadum, ụlọ ọrụ nyocha sayensị, wdg. Metal atomization powder nwere ike ịmepụta site na nnukwu nsogbu mmiri atomization dị ka ngwa ntụ ntụ.

Ngwa a dịkwa mma maka mmepụta na nyocha nke mmepụta ihe mgbakwunye ọla edo (nchacha ọla edo) nkwadebe ntụ ntụ na mahadum na ụlọ ọrụ nyocha sayensị.

Ngwa ahụ dịkwa mma maka nyocha na mmepụta nke ụdị igwe anaghị agba nchara, alloy steel, ntụ ntụ ọla kọpa, ntụ ntụ aluminum, ntụ ntụ ọlaọcha, seramiiki ntụ ntụ na ntụ ntụ brazing.

-

Igwe ihe nkedo na-aga n'ihu dị elu maka ihe ọhụrụ nkedo nkedo eriri ọla ọla ọcha ọla kọpa

Nkedo nke eletrọnịkị ihe ndị dị ka bond alloy ọlaọcha ọla kọpa waya na elu-ọcha pụrụ iche waya The imewe nke a ngwá usoro dabeere n'ezie mkpa nke oru ngo na usoro, na-eme ka n'ụzọ zuru ezu ojiji nke ọgbara ọhụrụ nkà na ụzụ technology.

1. Nabata nkà na ụzụ na-ekpo ọkụ na-ekpo ọkụ nke German, nlekota oge na-akpaghị aka na ọtụtụ teknụzụ nchebe, nke nwere ike gbazee n'ime obere oge, chekwaa ike ma rụọ ọrụ nke ọma.

2. Ụdị mechiri emechi + ụlọ na-agbaze gas nchebe inert nwere ike igbochi oxidation nke ihe ndị a wụrụ awụ na ngwakọta nke adịghị ọcha.Ngwa a dabara adaba maka nkedo nke ihe igwe dị elu dị ọcha ma ọ bụ ọla elemental oxidized dị mfe.

3. Jiri mechiri emechi + inert gas iji chebe ụlọ agbaze.Mgbe ọ na-agbaze na gburugburu gas na-adịghị agwụ agwụ, mfu oxidation nke carbon ebu fọrọ nke nta ka ọ bụrụ ihe na-adịghị mma.

4. Na ọrụ nke electromagnetic edemede + n'ibu na-akpali akpali n'okpuru nchebe nke inert gas, ọ dịghị nkewa na agba.

5. N'iji Ngosipụta Mmehie (mgbochi nzuzu) usoro njikwa akpaaka, ọrụ ahụ dị mfe karị.

6. N'iji usoro nchịkwa okpomọkụ nke PID, okpomọkụ dị mma karịa (± 1 ° C).

7. HVCC usoro elu agụụ na-aga n'ihu nkedo akụrụngwa na-onwe ya mepụtara na arụpụtara, na elu technology, eji maka na-aga n'ihu nkedo nke elu ịdị ọcha gold, ọlaọcha, ọla kọpa na ndị ọzọ alloys.

8. Ngwá ọrụ a na-eji Mitsubishi PLC usoro njikwa mmemme, SMC pneumatic na Panasonic servo moto mbanye na ihe ndị ọzọ nke ụlọ na nke mba ọzọ.

9. Na-agbaze na mechiri emechi + inert gas nchebe na-agbaze ụlọ, abụọ nri, electromagnetic akpali akpali, n'ibu akpali akpali, refrigeration, nke mere na ngwaahịa nwere àgwà nke dịghị oxidation, ala ọnwụ, dịghị porosity, ọ dịghị segregation na agba, na mara mma ọdịdị.

10. Ụdị Vacuum: Nnukwu oghere.

-

Vacuum na-aga n'ihu igwe nkedo maka ọla kọpa ọla edo ọla edo

Sistemụ nkedo na-aga n'ihu pụrụ iche

Maka ogo kacha mma nke ihe emechara ọkara:

Iji belata ihe ize ndụ nke oxidation n'oge agbaze na n'oge eserese, anyị na-elekwasị anya n'izere kọntaktị oxygen na ibelata ngwa ngwa nke okpomọkụ nke ihe metal a dọtara.

Atụmatụ iji zere kọntaktị oxygen:

1. Usoro gas inert maka ụlọ agbaze

2. Sistemụ oghere maka ụlọ na-agbaze - dị iche iche maka igwe igwe Hasung vacuum na-aga n'ihu (usoro VCC)

3. Inert gas flushing na anwụ

4. Ntụ okpomọkụ anwụ anya

5. Usoro nhazi nke abụọ ọzọ

6. Ihe ndị a niile dị mma karịsịa maka alloys nwere ọla kọpa dị ka ọla edo na-acha uhie uhie ma ọ bụ maka ọlaọcha ka ihe ndị a na-emekarị oxidise ngwa ngwa.Enwere ike ịhụ usoro eserese na ọnọdụ n'ụzọ dị mfe site na ikiri windo.

Ngosipụta oghere nwere ike ịdị ka arịrịọ ndị ahịa si dị.

-

Igwe ihe nkedo na-aga n'ihu maka ọla kọpa ọla edo ọla edo

Nhazi nke usoro akụrụngwa a dabere na ezigbo mkpa nke oru ngo na usoro, na-eji teknụzụ ọgbara ọhụrụ dị elu.

1. N'iji teknụzụ kpo oku dị elu nke German, nlekota ugboro ugboro na-akpaghị aka na ọtụtụ teknụzụ nchebe, enwere ike ịgbaze ya n'oge dị mkpirikpi, nchekwa ike na nchebe gburugburu ebe obibi, na ịrụ ọrụ dị elu.

2. Ụdị mechiri emechi + ụlọ na-agbaze gas nchebe inert nwere ike igbochi oxidation nke ihe ndị a wụrụ awụ ma gbochie ngwakọta nke adịghị ọcha.Ngwa a dabara adaba maka nkedo nke ihe igwe dị elu dị ọcha ma ọ bụ ọla elemental oxidized dị mfe.

3. N'iji ụlọ na-agbaze na-emechi emechi + inert gas na-agbaze, a na-eme ka agbaze na ikpo ọkụ na-eme n'otu oge ahụ, a na-ebelata oge ahụ, na mmepụta mmepụta na-abawanye nke ọma.

4. Na-agbaze na gburugburu ikuku gas na-adịghị, nkwụsị nke oxidation nke carbon crucible fọrọ nke nta ka ọ bụrụ ihe na-adịghị mma.

5. Na ọrụ mkpali electromagnetic n'okpuru nchebe nke inert gas, ọ dịghị nkewa na agba.

6. Ọ na-anabata Mmehie Ngosipụta (mgbochi nzuzu) sistemụ njikwa akpaka, nke dị mfe iji.

7. N'iji usoro nchịkwa okpomọkụ nke PID, okpomọkụ dị mma karịa (± 1 ° C).Usoro ihe nkedo HS-CC na-aga n'ihu bụ nke a na-emepụta onwe ya ma jiri teknụzụ dị elu rụọ ya ma raara onwe ya nye na agbaze na nkedo nke ọla edo, ọlaọcha, ọla kọpa na ihe ndị ọzọ alloys ibe, mkpanaka, mpempe akwụkwọ, ọkpọkọ, wdg.

8. Ngwá ọrụ a na-eji Mitsubishi PLC usoro njikwa mmemme, SMC pneumatic na Panasonic servo motor drive na ihe ndị ọzọ a ma ama nke ọma n'ụlọ na mba ọzọ.

9. Na-agbaze, electromagnetic ịkpali, na refrigeration na mechiri emechi + inert gas nchebe na-agbaze ụlọ, nke mere na ngwaahịa nwere àgwà nke dịghị oxidation, ala ọnwụ, ọ dịghị pores, ọ dịghị segregation na agba, na mara mma ọdịdị.