Ngwa Hasung-High Vacuum na-aga n'ihu na nkedo maka ọla dị oke ọnụ ahịa

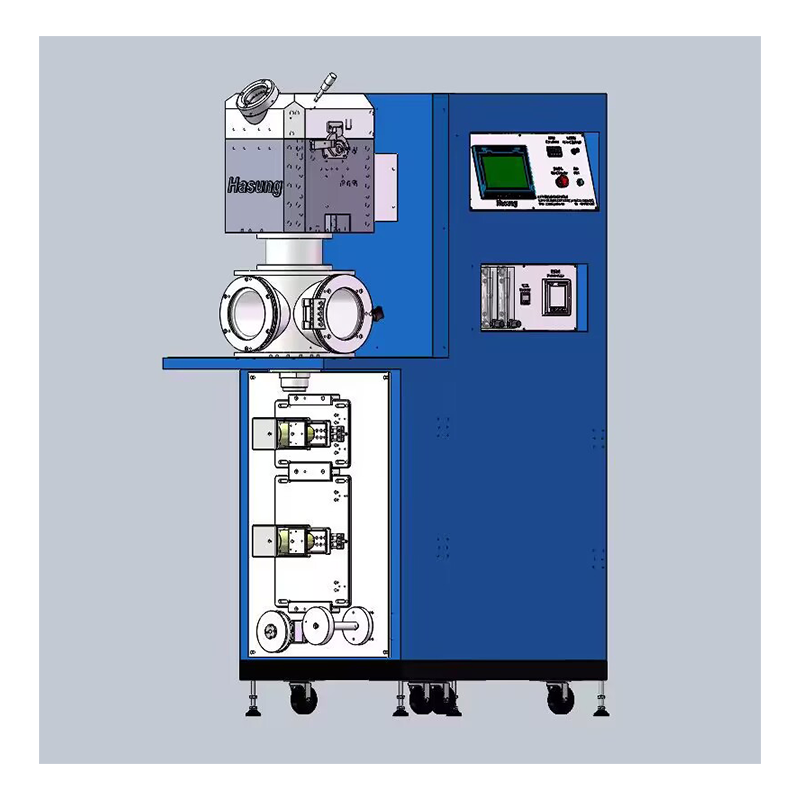

1. Nkọwa akụrụngwa:

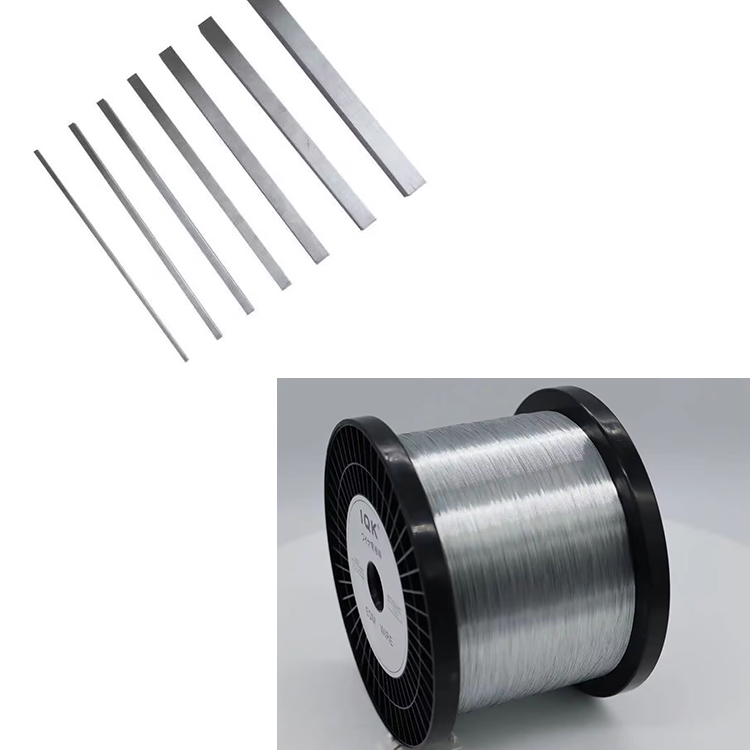

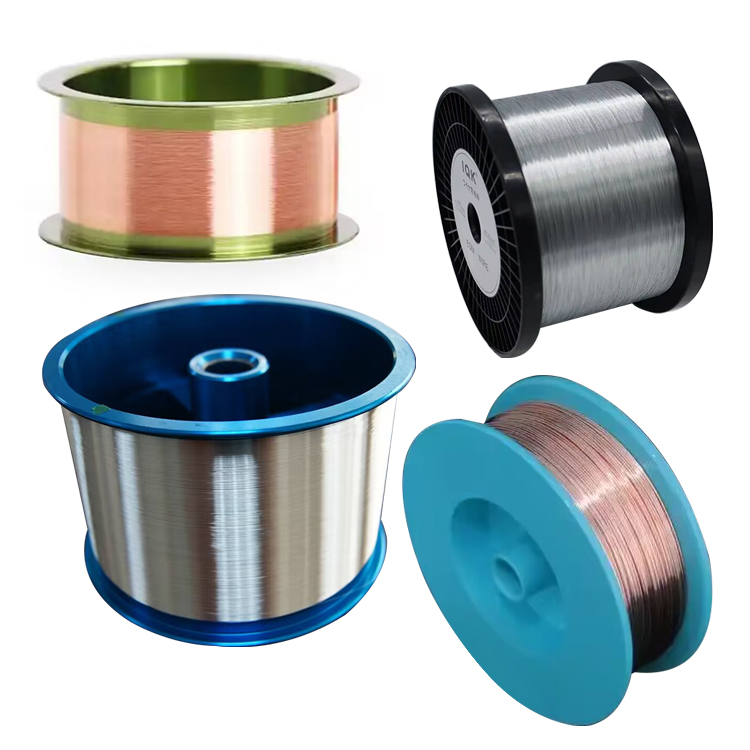

1. A na-eji akụrụngwa a na-aga n'ihu nkedo nke otu ogwe ọla kọpa kristal, ogwe ọla ọcha otu kristal, na ogwe ọla edo kristal, enwere ike iji ya mee ihe nkedo na-aga n'ihu nke ọla ndị ọzọ na alloys.

2. Ngwa a bụ ahụ ọkụ kwụ ọtọ. A na-etinye akụrụngwa, crucible, na crystallizer n'ime mkpuchi ọkụ meghere n'elu, a na-etinyekwa mkpanaka nduzi kristal n'akụkụ ala nke ọkụ ọkụ ahụ. Nke mbụ, a na-ewepụ kristal ahụ site na mgbaze site na ogologo oge site na mkpanaka nduzi kristal, mgbe ahụ, a na-edozi mkpanaka kristal na igwe ikuku maka ịbịaru na nchịkọta.

3. Nke a na ngwaọrụ adopts a ihuenyo mmetụ n'ụzọ zuru ezu akpaka akara usoro na otutu nlekota ngwaọrụ n'ụzọ ziri ezi ịchịkwa okpomọkụ nke ọkụ na crystallizer, ọbọ ogologo oge kwụsiri ike ọnọdụ chọrọ maka kristal ibu; Enwere ike ịme ọtụtụ ihe nchebe site na ngwa nlekota oru, dị ka ihe ntanye ihe mere site na elu ọkụ ọkụ, ezughị ezu agụụ, mmiri n'okpuru nrụgide ma ọ bụ ụkọ, wdg. The akụrụngwa dị mfe iji rụọ ọrụ, na isi parameters setịpụrụ gụnyere ọkụ ọkụ, okpomọkụ nke akụkụ elu, etiti na nke dị ala nke crystallizer, tupu ịdọrọ ọsọ, kristal ibu ịdọrọ ọsọ (yana ọnọdụ inch, nke pụtara ịdọrọ maka oge na nkwụsị maka oge), yana ụkpụrụ mkpu dị iche iche.

Igwe ihe nkedo Hasung Precious Metal na-akpaghị aka na-aga n'ihu

2, Main oru kwa nke akụrụngwa:

1. Ụdị: Vetikal, njikwa akpaka, kpo oku akpaka.

2. Mkpokọta ike ọkọnọ voltaji: atọ-phase 380V, 50Hz atọ-adọ

3. Ike ikpo ọkụ: 20KW

4. Usoro ikpo oku: Induction kpo oku (enweghị mkpọtụ)

5. Ike: 8kg (ọlaedo)

6. Oge ịgbaze: 3-6 nkeji

7. Okpomọkụ kachasị: 1600 Celsius

6. dayameta mkpanaka ọla: 6-10m

7. Vacuum ogo: Ọnọdụ oyi <6 67 × 10-3Pa

8. Okpomọkụ: 1600 ℃

9. Mkpanaka ọla kọpa na-adọkpụ ọsọ: 100-1500mm / min (mgbanwe)

10. Ọla a na-agba agba: ọla edo, ọla ọcha, ọla kọpa, na ihe alloy.

11. Usoro jụrụ oyi: Mmiri jụrụ oyi (mmiri okpomọkụ 18-26 degrees Celsius)

12. Ọnọdụ njikwa: Siemens PLC + ihuenyo mmetụ nwere ọgụgụ isi njikwa

13. Nha akụrụngwa: 2100 * 1280 * 1950mm

14. Ibu: Ihe dị ka 1500kg. Nnukwu agụụ: ihe dịka 550kg.

3. Isi nkọwa nhazi:

1. Igwe ọkụ ahụ: Igwe ọkụ ahụ na-anakwere nhazi mmiri oyi nke okpukpu abụọ. Enwere ike imeghe mkpuchi ọkụ maka ntinye dị mfe nke crucibles, crystallizers, na akụrụngwa. Enwere windo nlele na akụkụ elu nke mkpuchi ọkụ ahụ, nke nwere ike ịhụ ọnọdụ nke ihe a wụrụ awụ n'oge usoro agbaze. A na-ahazi flanges induction electrode flanges na vacuum pipeline flanges n'ụzọ dị iche iche n'ogo dị elu n'etiti ahụ ọkụ iji webata nkwonkwo induction electrode na jikọọ na oghere oghere. A na-eji efere nkwado ọkụ na-edozi ọkụ, nke na-ejekwa ozi dị ka ikpo ọkụ iji dozie ọnọdụ nke crystallizer n'ụzọ ziri ezi, na-ahụ na oghere etiti nke crystallizer na-etinye uche na ọwa akara na efere ala ọkụ. Ma ọ bụghị ya, mkpanaka nduzi kristal agaghị enwe ike ịbanye n'ime ime crystallizer site na ọwa akara. Enwere mgbanaka mmiri oyi atọ na etiti nkwado ahụ, kwekọrọ na elu, etiti na akụkụ ala nke crystallizer. A na-achịkwa ọnọdụ okpomọkụ nke akụkụ ọ bụla nke crystallizer nke ọma site n'ịchịkwa ọsọ nke mmiri jụrụ oyi. Enwere thermocouples anọ na etiti nkwado, nke a na-eji tụọ okpomọkụ nke elu, etiti, na akụkụ ala nke crucible na crystallizer, n'otu n'otu. The interface n'etiti thermocouples na n'èzí nke ọkụ dị na ọkụ ala efere. Enwere ike idowe akpa mkpofu na ala nke etiti nkwado iji gbochie okpomọkụ ịgbaze ka ọ na-agbada ozugbo site na ihe nchacha wee mebie ahụ ọkụ. Enwekwara obere ọnụ ụlọ na-enweghị isi nke nwere ike ịpụpụ n'ebe etiti dị na efere ala nke ọkụ. N'okpuru ọnụ ụlọ oghere na-adịghị ahụkebe bụ ụlọ enyo organic nke enwere ike ịgbakwunye ya na ihe na-egbochi oxidation iji melite oghere akara nke waya dị mma. Ihe nwere ike nweta mmetụta mgbochi oxidation n'elu mkpanaka ọla kọpa site n'ịgbakwunye ihe na-egbochi oxidation na oghere iko organic.

2. Crucible na Crystallizer: A na-eme crucible na crystallizer nke graphite dị elu. Ala nke crucible bụ conical ma jikọọ na crystallizer site na eri.

3. Sistemụ agụụ:

1. Mgbọrọgwụ mgbapụta

2. Pneumatic elu oghere diski valve

3. Electromagnetic elu agụụ onu oriri valvụ

4. Ihe nlele dị elu

5. Obere oghere nlele

6. ahụ ọkụ

7. Pneumatic elu agụụ baffle valve

8. Ọnyà oyi

9. Mgbasa mgbasa ozi

4. Usoro ịse na winding: Nkedo ọla kọpa na-aga n'ihu na-enwe wiil ntuziaka, mkpanaka ịghasa nkenke, ntuziaka linear, na usoro ikuku. Wheel ntuziaka na-arụ ọrụ nduzi na nhazi, na ihe mbụ mkpara ọla kọpa na-agafe mgbe ọ na-esi na ọkụ pụta bụ wheel ndu. A na-edobere mkpanaka nduzi kristal na nkenke nkenke na ngwaọrụ ntuziaka linear. A na-ebu ụzọ wepụta mkpanaka ọla kọpa n'anụ ọkụ ahụ (tupu ebupụtara) site na mmegharị ahịrị ahịrị nke mkpanaka ndu kristal. Mgbe mkpanaka ọla kọpa na-agafe na wiil nduzi ma nwee ogologo oge, njikọ na mkpanaka nduzi crystallization nwere ike ebipụ. Mgbe ahụ, a na-edozi ya na igwe ikuku ma na-aga n'ihu na-adọta mkpanaka ọla kọpa site na ntụgharị nke igwe ikuku. The servo moto na-achịkwa linear ngagharị na ntụgharị nke winding igwe, nke nwere ike kpọmkwem ịchịkwa na-aga n'ihu nkedo ọsọ nke ọla kọpa mkpara.

5. Igwe ọkụ ultrasonic nke sistemụ ike na-anabata German IGBT, nke nwere obere mkpọtụ na nchekwa ike. Olulu mmiri ahụ na-eji ngwa njikwa okpomọkụ maka kpo oku a na-ahazi. Nhazi usoro eletrik

Enwere mgbakasị ahụ, nzaghachi overvoltage na sekit nchebe.

6. Control usoro: Nke a na ngwá adopts a ihuenyo mmetụ n'ụzọ zuru ezu akpaka akara usoro na otutu nlekota ngwaọrụ n'ụzọ ziri ezi ịchịkwa okpomọkụ nke ọkụ na crystallizer, ọbọ ogologo oge kwụsiri ike ọnọdụ chọrọ maka ọla kọpa mkpara na-aga n'ihu nkedo; Enwere ike ịme ọtụtụ ihe nchebe site na ngwa nlekota oru, dị ka ihe ntanye ihe mere site na nnukwu ọkụ ọkụ, ezughị ezu agụụ, mmiri n'okpuru nrụgide ma ọ bụ ụkọ, wdg. Ngwá ọrụ dị mfe iji rụọ ọrụ ma na-edozi ihe ndị bụ isi.

Enwere okpomọkụ ọkụ, okpomọkụ nke elu, etiti, na akụkụ ala nke crystallizer, ọsọ ịdọrọ tupu, na ọsọ kristal na-adọta.

Na ụkpụrụ mkpu dị iche iche. Mgbe ịtọsịrị paramita dị iche iche, na usoro mmepụta nke mkpanaka ọla kọpa na-aga n'ihu, ọ bụrụhaala na echekwara nchekwa

Debe mkpanaka ndu kristal, tinye akụrụngwa, mechie ọnụ ụzọ ọkụ, bepụ njikọ dị n'etiti mkpanaka ọla kọpa na mkpanaka kristal, ma jikọọ ya na igwe ikuku.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur